Montreal, Quebec – May 3, 2023 – Lomiko Metals Inc. (TSX.V: LMR) (“Lomiko Metals” or the “Company”) is pleased to announce results of the spherical graphite (“SPG”) lab scale testing for its La Loutre Natural flake Graphite property (‘’La Loutre Project’’), located approximately 180 kilometres northwest of Montréal in the Laurentian region of Québec. The La Loutre Project is located within the Kitigan Zibi Anishinabeg (KZA) First Nation’s territory. The testing was completed by ProGraphite in Germany on a 10.5 kg bulk flotation sample prepared by SGS Canada Inc. The 10.5 kg bulk flotation concentrate was generated during the preliminary feasibility study (PFS) metallurgical program and was dispatched to ProGraphite in Germany for micronization, spheroidization, and purification testing to produce spheroidized and purified graphite (SPG), which is the needed material for the anode in Electric Vehicles (EVs).

Highlights of the La Loutre Project SPG lab scale testing:

- La Loutre material is suitable for the production of spherical

- All physical characterization tests produced very good results such as narrow particle size distribution range and high tap density and meet the target values for Electric Vehicle and other lithium-ion based battery applications.

- Achieved continuous and reliable production of micronized products with homogenous properties suggesting a relatively low specific energy input to convert the La Loutre flotation concentrate to micronized material.

- The particle size distribution for both grades is typical for spherical

In summary, independent bench scale micronization and spheronization tests have demonstrated that the La Loutre material is suitable for the production of spherical graphite. All physical data yielded very good results and meet the target values such as narrow particle size distribution and high tap density.

Belinda Labatte, CEO and Director stated: “We are very pleased to achieve a high purity SPG graphite from La Loutre graphite flotation concentrate. It is very encouraging to see that the lab scale level of metallurgical testing shows that Lomiko can achieve a purity of 99.99% C(g) with a yield of approximately 55%. We are looking forward to further purification testing and coating trials and the of start the battery trials in the next quarter. We believe this to be an important step in validating the geological and metallurgical potential of the deposit for a climate success story, and directly feeding into the North American EV supply chain. We look forward to the next steps including more field work, and discussions with KZA First Nation and local communities.”

The flotation concentrate was analysed for the two most important parameters of flake graphite concentrates, namely the particle size distribution and the carbon content. The results of the analysis is presented in Table 1.

Table 1: Screen analysis and LOI of the graphite flotation concentrate

| Name | Grade | Screening | LOI % | ||||||

| Micron | +300 | +180 | +150 | +100 | +71 | +40 | minus | ||

| Mesh | +50 | +80 | +100 | +150 | +200 | +325 | minus | ||

| Lomiko | Concentrate S#2225 | 13.2 | 19.4 | 9.8 | 18.3 | 12.9 | 16.9 | 9.6 | 97.38 |

The loss on ignition (LOI) value of the flotation concentrate was high at 97.4% (this is achieved by flotation only using a bulk sample produced by SGS).

A higher carbon content in the flotation concentrate is advantageous for subsequent purification, as this normally results in lower operating costs and possibly even lower capital costs. The sieving also shows a positive result: despite the high carbon content, the concentrate is relatively coarse with approximately 40% flakes over 100 mesh.

Spheronization and purification

Typical production steps to obtain spherical purified graphite (SPG) are micronizing, spheronizing and purification.

The target size of two spherical graphite products was a d50 (50% of the mass being smaller than a specific size) of approximately 15 micron and 20 microns respectively.

The flowability of the feed material was good and the micronizing throughput was on a rather high level, which suggests a relatively low specific energy input to convert the La Loutre flotation concentrate to micronized material. It was possible to continuously produce micronized products with homogenous properties.

In addition to the particle size distribution, other physical parameters were analysed. The results are shown in Table 2.

Table 2 : Properties of Spheronized Graphite

| Feed Grade | Run | Target size d50 | Particle Size Distribution | Ratio d90/10 | ||

| d10 | d50 | d90 | ||||

| Concentrate S#2225 | M102 M1 | 20 | 5.50 | 20.70 | 39.5 | 7.2 |

| M102 M3 | 15 | 4.10 | 15.30 | 31.6 | 7.7 | |

The specific surface area was measured with the BET method. For the spheronized graphite SPG20 it was analysed at 7.4 m²/g, which is a normal value for material that was produced with a batch spheronizer. As expected, the BET value for the SPG16 of 8.20 m²/g is slightly higher since a smaller particle size corresponds to higher BET values.

The tap density, especially for the SPG20 (0.96 kg/l) is very good for SPG material prior to coating. A high tap density is preferred as it results in batteries with higher capacities.

Typical yield levels for batch process are around 50%, which were exceeded by the La Loutre graphite at 55%.

Purification test work

Two purification methods were investigated on the La Loutre SPG, namely alkaline and acid purification.

A total of 100 g of the SPG20 spherical graphite was subjected to an intensive alkaline purification. The main chemical employed was sodium hydroxide (NaOH). An alkaline digestion at 250°C followed by a sulphuric acid (H2SO4) wash was carried out. The purified SPG material graded 99.97% LOI, which exceeded the minimum grade requirements of SPG material for electric vehicle (EV) application of 99.95% LOI.

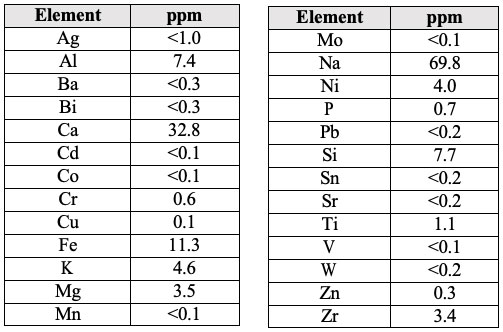

The purified graphite ash was examined by an ICP analysis The results of the ICP scan are presented in Table 2.

Table 3: ICP Results of Graphite Purified with Alkaline Purification Process

The concentrations of all impurities were at very low levels and especially concentrations of critical elements for use in batteries, such as Fe, Cr, Cu, Si are below the typical specification limits. The excellent values for Fe and Si confirm that the purification was very successful.

Two elements, namely sodium (Na) and calcium (Ca) were elevated. The higher sodium levels were likely linked to the NaOH digestion and can possibly be reduced significantly by further optimization of the purification process conditions.

The same SPG20 material that was subjected to alkaline purification was also used for the acid purification tests. The acid purification employs HF (hydrofluoric acid) as the main chemical, due to its ability to dissolve most of the silicates and many other impurities. Minor portions of other acids were added as well.

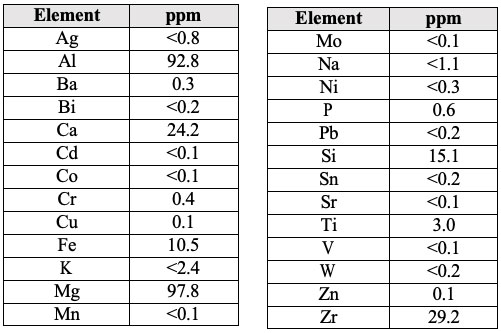

A strong acid purification process with several steps was carried out to reach the battery grade levels of purities. Material handling properties of the SPG such as filtration was favourable. However, incinerating (ashing) of the purified graphite produced a white residue, and the purity was at 99.94% LOI. The results of an ICP-scan that was performed on the acid purified SPG20 material is presented in Table 4.

Table 4: ICP Results for Acid Purified SPG20 Material

The values for silicon and iron are very low, which indicates that the cleaning went well. However, it can be seen that the values for aluminum and magnesium are significantly higher. It is postulated that these elements were primarily responsible for the white ash.. A second HF purification test with an increased acid concentration failed to reduce the elevated aluminum and magnesium concentrations.

It was then decided that two options should be explored to further reduce the contamination of impurities:

- pre-purification prior to HF purification with a mixture of hydrochloric and nitric acid,

- a post-treatment of the material that was purified with HF with sulfuric

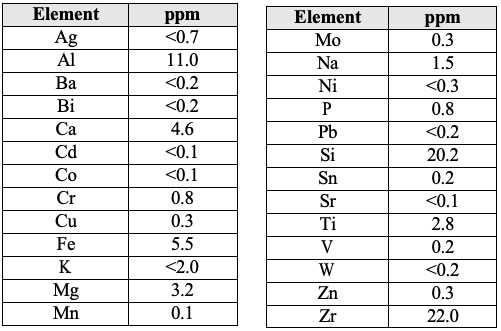

Both options produced very good results, and the white ash was no longer observed. The sample that was generated with post-treatment of the HF purified SPG20 material with sulphuric acid was incinerated and the ash/remining residue was submitted for an ICP analysis. The purified material graded 99.99% LOI, and the results of the ICP- analysis are presented in Table 5.

Table 5: ICP Results of Graphite Purified with Advanced HF Purification Process

The concentrations of aluminum and magnesium were reduced by approximately 90% and 97%, respectively. Concentrations of other impurities such as calcium, iron, and zirconium were also reduced noticeably.

Next steps

Parallel purification work will be conducted by Corem in Quebec City, where Corem will further upgrade the SPG material by carbon coating into coated, spheroidized, and purified graphite (CSPG), which will then be evaluated in battery trials by Polaris Battery Labs. Complete test results are expected in late Q2 or early Q3 2023. The Company continues to actively work with partners in Quebec for battery trials as a next step.

The Company’s updated investor presentation and website can be found at www.lomiko.com.

Qualified Persons

Mr. Oliver Peters, a Principal Metallurgist with Metpro Management Inc., is a Qualified Person within the meaning of NI 43-101. Mr. Peters is satisfied that the analytical and testing procedures used are standard industry operating procedures and methodologies, and he has reviewed, approved and verified the technical information disclosed in this news release, including sampling, analytical and test data underlying the technical information.

About Lomiko Metals Inc.

The Company holds mineral interests in its La Loutre Project in southern Quebec. The La Loutre project site is located within the Kitigan Zibi Anishinabeg (KZA) First Nation’s territory. The KZA First Nation is part of the Algonquin Nation and the KZA traditional territory is situated within the

Outaouais and Laurentides regions. Located 180 kilometres northwest of Montreal, the property consists of one large, continuous block with 76 mineral claims totalling 4,528 hectares (45.3 km2).

The Property is underlain by rocks belonging to the Grenville Province of the Precambrian Canadian Shield. The Grenville was formed under conditions that were very favourable for the development of coarse-grained, flake-type graphite mineralization from organic-rich material during high- temperature metamorphism.

Lomiko Metals published a April 13, 2023 Updated Mineral Resource Estimate (MRE) which estimated 68.2 million tonnes of Indicated Mineral Resources averaging 4.50% Cg per tonne for

3.072 million tonnes of graphite, a tonnage increase of 195%. Indicated Mineral Resources increased 45.01 million tonnes as a result of the 2022 drilling campaign, from 23.2 million tonnes in 2021 MRE with additional Mineral resources reported down-dip and within marble units resulted in the addition of 21.8 million tonnes of Inferred Mineral Resources averaging 3.51% Cg per tonne for 0.765 million tonnes of contained graphite; and the additional 13,107 metres of infill drilling in 79 holes completed in 2022 combined with the refinement of the deposit and structural models contributed to the addition of most of the Inferred Mineral Resources to the Indicated Mineral Resource category, relative to the 2021 Mineral Resource estimate. The MRE assumes a US$1,098.07 per tonne graphite price and a cut-off grade of 1.50%Cg (graphitic carbon).

In addition to La Loutre, Lomiko is working with Critical Elements Lithium Corporation towards earning its 70% stake in the Bourier Project as per the option agreement announced on April 27th, 2021. The Bourier project site is located near Nemaska Lithium and Critical Elements southeast of the Eeyou Istchee James Bay territory in Quebec which consists of 203 claims, for a total ground position of 10,252.20 hectares (102.52 km2), in Canada’s lithium triangle near the James Bay region of Quebec that has historically housed lithium deposits and mineralization trends.

On behalf of the Board, Belinda Labatte

CEO and Director, Lomiko Metals Inc.

For more information on Lomiko Metals, review the website at www.lomiko.com

Contact Gordana Slepcev at 647-391-7344 or Belinda Labatte at 647-402-8379 or at 1-833-456- 6456 or 1-833-4-LOMIKO

or email: info@lomiko.com.

Cautionary Note Regarding Forward-Looking Information

This news release contains “forward-looking information” within the meaning of the applicable Canadian securities legislation that is based on expectations, estimates, projections and interpretations as at the date of this news release. The information in this news release about the Company; and any other information herein that is not a historical fact may be “forward-looking information” (“FLI”). All statements, other than statements of historical fact, are FLI and can be identified by the use of statements that include words such as “anticipates”, “plans”, “continues”, “estimates”, “expects”, “may”, “will”, “projects”, “predicts”, “proposes”, “potential”, “target”, “implement”, “scheduled”, “intends”, “could”, “might”, “should”, “believe” and similar words or expressions. FLI in this new release includes, but is not limited to: expected timing and impact of completion of further purification testing and coating trials for its La Loutre Natural flake Graphite property; anticipated timing of battery trials with its partners and timing to achieve certain milestones; and the Company’s ability to successfully fund, or remain fully funded for the implementation of its business strategy and for exploration of any of its projects (including from the capital markets). FLI involves known and unknown risks, assumptions and other factors that may cause actual results or performance to differ materially. This FLI reflects the Company’s current views about future events, and while considered reasonable by the Company at this time, are inherently subject to significant uncertainties and contingencies. Accordingly, there can be no certainty that they will accurately reflect actual results. Assumptions upon which such FLI is based include, without limitation: the ability of the Company to successfully produce in the future, in sufficient commercial quantities, spheroidized and purified graphite (SPG), which is the needed material for the anode in Electric Vehicles (EVs); ability to implement its business strategy and to fund, explore, advance and develop each of its projects, including results therefrom and timing thereof; uncertainties related to receiving and maintaining exploration, environmental and other permits or approvals in Quebec; unforseen impacts of COVID-19 on the Company’s business objectives or projects and the Company’s financial position or operations; impact of increasing competition in the mineral exploration business, including the Company’s competitive position in the industry; general economic conditions, including in relation to currency controls and interest rate fluctuations.

The FLI contained in this news release are expressly qualified in their entirety by this cautionary statement, the “Forward-Looking Statements” section contained in the Company’s most recent management’s discussion and analysis (MD&A), which is available on SEDAR at www.sedar.com, and on the investor presentation on its website. All FLI in this news release are made as of the date of this news release. There can be no assurance that such statements will prove to be accurate, as actual results and future events could differ materially from those anticipated in such statements. Accordingly, readers should not place undue reliance on forward-looking information. The Company does not undertake to update or revise any such forward-looking statements or forward- looking information contained herein to reflect new events or circumstances, except as may be required by applicable securities laws.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this news release.